-

Crushing Equipment

Jaw Crusher HP Hydraulic Cone Crusher PF Impact Crusher Heavy Hammer Crusher European Version Impact Crushe Roller Crusher Single Cylinder Hydraulic Cone PC Hammer Crusher Box Crusher Hydraulic Cone Crusher

-

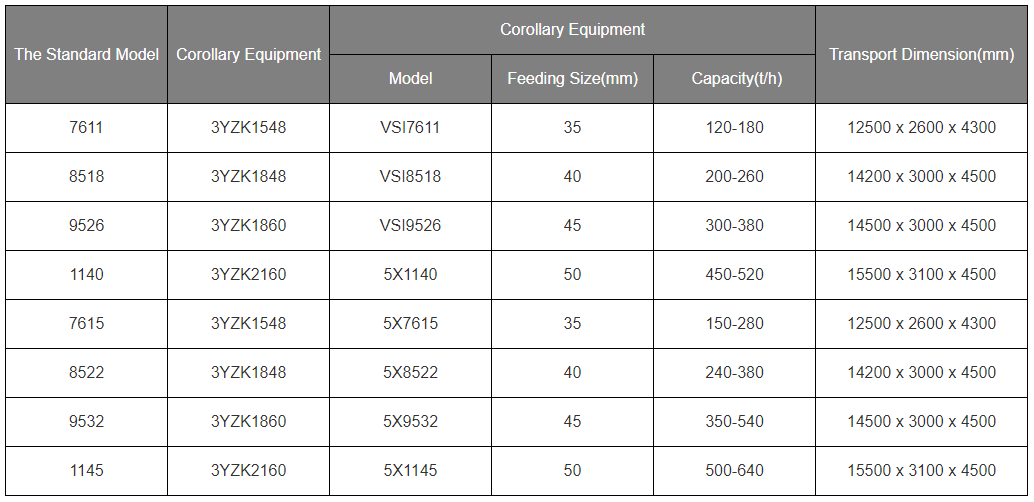

Sand Making Equipment

VSI High Efficiency Sand Makin 5X High Efficiency Vertical Sh Compound Sand Making Machine PXJ Sand Making Machine

-

Sand Washing Equipment

Wheel Sand Washing Machine Spiral Sand Washing Machine Fine Sand Recycling Machine Belt Conveyors Vibrating Feeder Circular Vibrating Screen

-

Mobile Crushing Plant

Tire Mobile Crushing Station Mobile Impact Crushing Station Mobile Cone Crusher Station Mobile Primary Crushing Crushi Crawler Mobile Screening and F Crawler Mobile Rough Crushing

-

Grinding Equipment

Raymond Mill Ball Mill Ultrafine Mill Vertical Roller Mill European Version Grinding Mill Coarse Powder Mill

- Crushing Equipment Jaw Crusher HP Hydraulic Cone Crusher PF Impact Crusher Heavy Hammer Crusher European Version Impact Crusher Roller Crusher Single Cylinder Hydraulic Cone Crusher PC Hammer Crusher Box Crusher Hydraulic Cone Crusher

- Sand Making Equipment VSI High Efficiency Sand Making Machine 5X High Efficiency Vertical Shaft Impact Sand Making Machine Compound Sand Making Machine PXJ Sand Making Machine

- Sand Washing Equipment Wheel Sand Washing Machine Spiral Sand Washing Machine Fine Sand Recycling Machine Belt Conveyors Vibrating Feeder Circular Vibrating Screen

- Mobile Crushing Plant Tire Mobile Crushing Station Mobile Impact Crushing Station Mobile Cone Crusher Station Mobile Primary Crushing Crushing Station Crawler Mobile Screening and Fine Crushing Station Crawler Mobile Rough Crushing Station

- Grinding Equipment Raymond Mill Ball Mill Ultrafine Mill Vertical Roller Mill European Version Grinding Mill Coarse Powder Mill

+86 155 1713 3739

+86 155 1713 3739 sandy@langbomachine.com

sandy@langbomachine.com 15517133739(Whatsapp/Wechat)

15517133739(Whatsapp/Wechat) Zhengzhou City, Henan Province, China

Zhengzhou City, Henan Province, China