High Pressure Suspension Mill Meets the Requirement of National Dust-dump Standard.it is Mainly Used to Process More Than 200 Kinds of Non-inflammable, Non-explosive and Brittle Materials with Moh’s Hardness Under 6 Scales

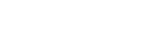

Feeding Size: 50-850mm

The Discharging Size: 0.074-0.89mm

Processing Capacity: 0.4-16t/h

Applied Material: barite, marble, talcum, calcite, dolomite, kaoline, coal, gypsum, concrete etc

Details Overview: High Pressure Suspension Mill meets the requirement of national dust-dump standard.It is mainly used to process more than 200 kinds of non-inflammable,

Introduction

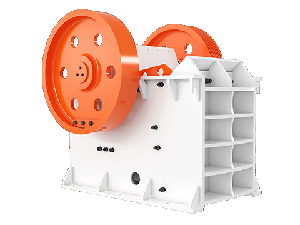

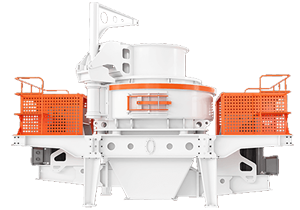

High Pressure Suspension mill is mainly made up of the mainframe, separator, blower, finished powder cyclone collector, bag filter and connecting pipes, etc.

According to users’ need, the mill can also be equipped with accessory equipments like crusher, bucket elevators, hopper, electromagnetic vibrating feeder and switch box, etc. Inside the mainframe, the roller subassembly is suspended on the roller suspender through horizontal supporting axis, and the roller suspender fixed up with the main shaft and shovel stand. Located outside of the roller bearing house, the pressure springs make rollers push down the inside surface of ring through horizontal supporting axis. Shovels installed on the shovel stand and rollers rotate together when the motor drives main shaft through transmission device and the rollers roll appressed the inside surface of ring and rotate at the same time. The separator impellers are driven by motor through transmission device to rotate, more higher the speed of separator impellor, more fine the powders been separated.

Features

1. Compared with other mills, its capacity increases by 10%-20% under the same power condition, and compression force of rollers to material improve 800-1200kgf under the force of high-pressure spring.

2. Size of final product can be 0.613mm (30mesh) –0.033mm (425mesh). Some can reach the fineness of 0.013mm (1000 mesh).

3. High Pressure Suspension Mill meets the requirement of national dust-dump standard.

4. The separator can be adjusted very easily.

5. The multi-class seals are adopted to keep the grinding equipment tightly closed.

High Pressure Suspension mill is mainly made up of the mainframe, separator, blower, finished powder cyclone collector, bag filter and connecting pipes, etc.

According to users’ need, the mill can also be equipped with accessory equipments like crusher, bucket elevators, hopper, electromagnetic vibrating feeder and switch box, etc. Inside the mainframe, the roller subassembly is suspended on the roller suspender through horizontal supporting axis, and the roller suspender fixed up with the main shaft and shovel stand. Located outside of the roller bearing house, the pressure springs make rollers push down the inside surface of ring through horizontal supporting axis. Shovels installed on the shovel stand and rollers rotate together when the motor drives main shaft through transmission device and the rollers roll appressed the inside surface of ring and rotate at the same time. The separator impellers are driven by motor through transmission device to rotate, more higher the speed of separator impellor, more fine the powders been separated

Working principle

When entering grinding chamber, the raw materials are shoveled up by the shovels and grinded between the rollers and ring; the materials after grinding are brought into the separator along with the air from the blower, and the qualified fine powder became final products and come into the cyclone powder collector, the other unqualified powder fall down to be re-grinded. The circular air returns back to the blower that the above process will be repeated, and the remaining air enters the bag filter in order to protect the environment.

+86 155 1713 3739

+86 155 1713 3739 sandy@langbomachine.com

sandy@langbomachine.com 15517133739(Whatsapp/Wechat)

15517133739(Whatsapp/Wechat) Zhengzhou City, Henan Province, China

Zhengzhou City, Henan Province, China